Originally Posted by

TREVELLY

Battery compartment and bilge pump compartment have drain holes out to back of boat - dry in calm sea submerged in any choppy sea hence water constantly drains into these compartments then on battery side into subfloor to bilge - so I get bilge every 20 minutes.

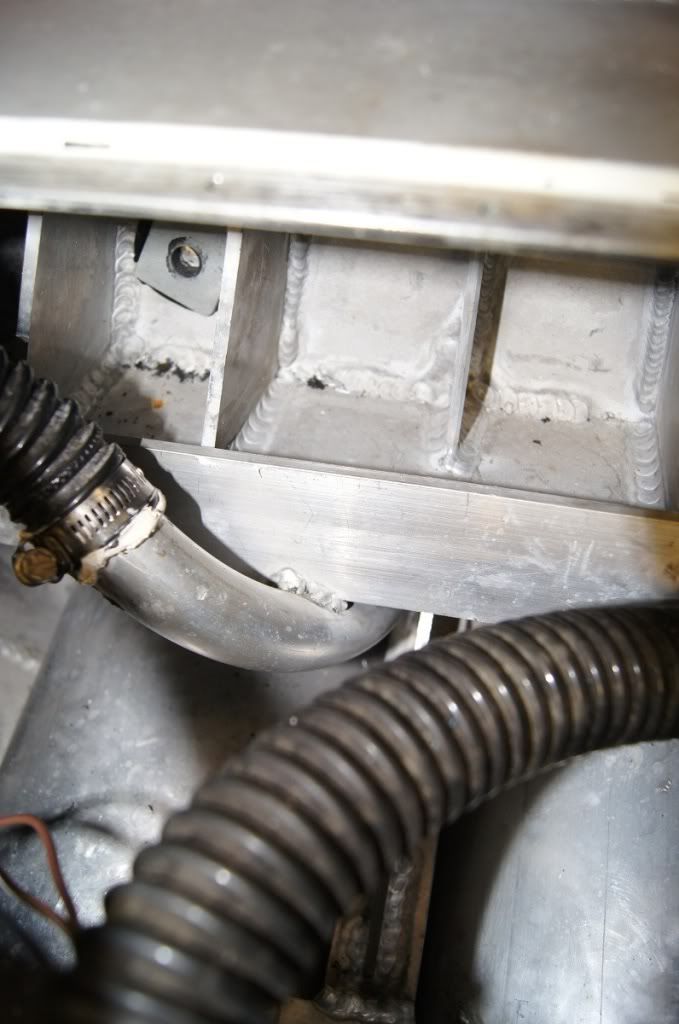

Some things are definitely happening at the factory - when I drained washdown pump compartment into subfloor (I drilled a hole) I was surprised it didn't come out the back drain holes, so I openned the inspection lids to area between motor and fuel tank - there is a partition with bung to isolate subfloor motor compartment to main subfloor - this bung was in and had heaps of finishing product on it - body filler call it what you will - took out the bung and the main subfloor then drained to rear letting out about 100 litres of water - is this smart? the front gets water in it cannot drain out rear or reach the bilge. Also the inspection lids between motor and back of boat - one had an "O"-ring seal and the other had none and looked like it never has - this is constantly under water and filling the boat on a choppy day - I bet I have to buy a complete inspection kit just to get a seal that should have been there.

GUYS I am not a whinger and most of it is attention to detail and to be honest I would have said nothing of this EXCEPT now having to rewire the boat I am really pissed!

You guys have a magnificient design hull but things like now having to rewire it more than take the shine off.

Reply With Quote

Reply With Quote